Hydraulic water pump spray dust suppression is a technology that uses hydraulic driven water pump to produce spray to achieve the purpose of dust suppression.

This method has the following advantages:

advantage:

1. Efficient dust reduction: It can quickly and effectively capture dust particles in the air, reducing dust pollution.

2. Strong adaptability: It can operate in various complex environments and working conditions, such as mines, construction sites, etc.

3. Continuous stability: the hydraulic drive is relatively stable and reliable, which can ensure the continuous progress of spray.

4. Good atomization effect: It can form small and uniform water mist, improving dust reduction efficiency.

Its working principle is usually to provide power for the water pump through the hydraulic system, so that the water pump pressurizes the water to form a spray through the nozzle. The fine water mist combines with the dust in the air to make the dust heavier and settle down, so as to achieve the effect of purifying the air and reducing the dust concentration. It has been widely used in some industrial and engineering fields, which is of great significance for improving the working environment and ensuring the health of personnel.

Hydraulic pump spray dust suppression technology is widely used in the following regions and industries:

Region:

1. Mining areas, including coal mines, metal mines, etc., have severe dust pollution and require dust reduction.

2. Urban areas with many construction sites generate a large amount of dust during the construction process.

Industry:

1. Mining industry: the mining and beneficiation processes of various types of mines.

2. Construction industry: in construction sites, such as earthwork operations, demolition projects, etc.

3. Road construction industry: in the process of road construction and maintenance.

4. Cement plant: A large amount of dust is generated during production and material processing.

5. Steel plant: steelmaking, ironmaking and other processes.

6. Thermal power plants: coal transportation, storage, and combustion processes.

7. Port terminals: Dust is easily generated during the loading, unloading, and transportation of goods.

8. Railway engineering: tunnel construction, roadbed construction, etc.

The dust suppression effect of hydraulic pump spray dust suppression technology in specific application scenarios is usually significant, which is mainly reflected in the following aspects:

In mining scenarios, it can effectively reduce the dust concentration in mining faces, transportation roads, and other areas, improve the working environment of miners, and reduce the risk of occupational diseases such as silicosis.

At construction sites, dust can be significantly reduced, resulting in a significant decrease in particulate matter content in the air and reducing its impact on the surrounding environment and residents.

In road construction, it has a good effect on suppressing dust dispersion and ensuring air quality in the construction area and nearby areas.

In industrial places such as cement plants and steel plants, the dust content in the workshop can be greatly reduced, and the cleanliness and safety of the working environment can be improved.

However, its dust suppression effect will also be affected by some factors, such as spray particle size, spray volume, coverage, wind speed, etc. By designing and adjusting parameters reasonably, its dust reduction effect can be better utilized to achieve the desired dust reduction effect. But the specific effect still needs to be comprehensively evaluated based on the actual application situation and monitoring data.

success cases

-Coal mining: The complete set of dust source zoning and enclosed dust prevention technology and equipment developed by China Coal Science and Industry Group Chongqing Research Institute Co., Ltd. for large mining height fully mechanized mining face has been successfully tested in the Beilianta Coal Mine of Shendong Coal Group and Caojiatan Mining Company of Shaanxi Coal Group, greatly improving the dust reduction efficiency of large mining height fully mechanized mining face.

-Underground coal mining: After the use of intelligent visual spray in Tunlan Mine of Xishan Coal Power Co., Ltd. of Shanxi Coking Coal Mine, problems such as high failure rate, small spray area and large water consumption of the original spray system have been improved. With the help of the automatic monitoring of the visual probe, manpower has been saved, the amount of dust fall underground has been increased, and the health of miners has been protected.

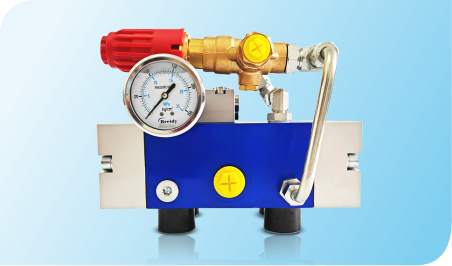

HPW series hydraulic high-pressure water pump

HPW200/30-45 、HPW200/30-45-ST、 HPW420/20-50-PA 、HPW420/20-50-PA、HPW220/50-70、HPW220/50-70-PA、HPW220/50-70MOBI、HPW90/150-85、HPW90/150-85-PA、HPW520/30-85、HPW520/30-85-PA、HPW180/90-115、HPW320/75-115、HPW800/30-140

HPW200/30-45 、HPW200/30-45-ST、 HPW420/20-50-PA 、HPW420/20-50-PA、HPW220/50-70、HPW220/50-70-PA、HPW220/50-70MOBI、HPW90/150-85、HPW90/150-85-PA、HPW520/30-85、HPW520/30-85-PA、HPW180/90-115、HPW320/75-115、HPW800/30-140

HPW200/30-45 、HPW200/30-45-ST、 HPW420/20-50-PA 、HPW420/20-50-PA、HPW220/50-70、HPW220/50-70-PA、HPW220/50-70MOBI、HPW90/150-85、HPW90/150-85-PA、HPW520/30-85、HPW520/30-85-PA、HPW180/90-115、HPW320/75-115、HPW800/30-140

HDF series hydraulic high-pressure water pump

HDF20/60、HDF50/45、HDF80/100、HDF80/160、HDF80/180、HDF80/250、HDF80/320、HDF80/450、HDF520/30、HDF90/150、HDF80/500、HDF200/100、HDF20/250、HDF100/600、HDF100/1200、HDF1200/100、HDF600/200、HDF180/23-35

HDF20/60、HDF50/45、HDF80/100、HDF80/160、HDF80/180、HDF80/250、HDF80/320、HDF80/450、HDF520/30、HDF90/150、HDF80/500、HDF200/100、HDF20/250、HDF100/600、HDF100/1200、HDF1200/100、HDF600/200、HDF180/23-35

HDF20/60、HDF50/45、HDF80/100、HDF80/160、HDF80/180、HDF80/250、HDF80/320、HDF80/450、HDF520/30、HDF90/150、HDF80/500、HDF200/100、HDF20/250、HDF100/600、HDF100/1200、HDF1200/100、HDF600/200、HDF180/23-35

返回

返回